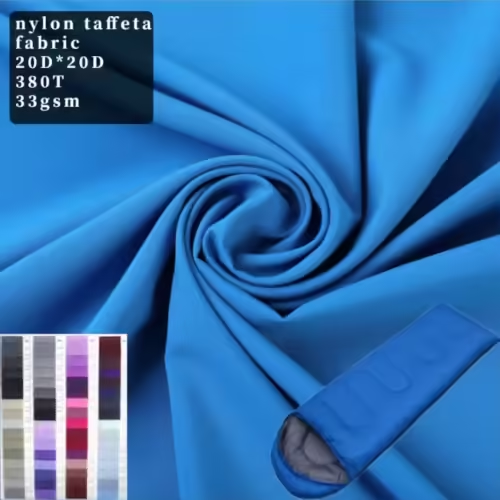

Material Composition:

Our 20D 380T Nylon fabric is meticulously crafted from high-tenacity nylon fibers. The “20D” refers to the denier count, indicating the fabric’s lightweight nature, while “380T” denotes the thread count, ensuring a tight weave for enhanced strength and durability. The fabric is further treated with a PU (polyurethane) and silicone coating, providing exceptional water resistance and UV protection.

Key Features:

1. Lightweight and Strong:

The 20D denier count ensures that the fabric is incredibly lightweight, making it perfect for paragliders where weight is a critical factor. Despite its lightness, the 380T thread count ensures that the fabric remains strong and durable, capable of withstanding the rigors of paragliding.

2. PU and Silicone Coating:

The dual coating of PU and silicone offers multiple benefits. The PU coating provides excellent water resistance, ensuring that the fabric remains dry even in wet conditions. The silicone coating adds an extra layer of protection against UV rays, preventing the fabric from degrading over time due to sun exposure. This combination ensures that the fabric maintains its integrity and performance in various weather conditions.

3. Superior Tear Resistance:

The high-tenacity nylon fibers and tight weave contribute to the fabric’s exceptional tear resistance. This is crucial for paragliders, as the fabric must withstand significant stress and strain during flight. Our 20D 380T Nylon fabric is designed to handle these demands, providing peace of mind for pilots.

4. Enhanced Air Retention:

The tight weave and coating also enhance the fabric’s air retention capabilities. This is particularly important for paragliders, as maintaining consistent air pressure within the wing is essential for stable flight. Our fabric ensures that air leakage is minimized, contributing to a safer and more reliable paragliding experience.

5. Versatile Applications:

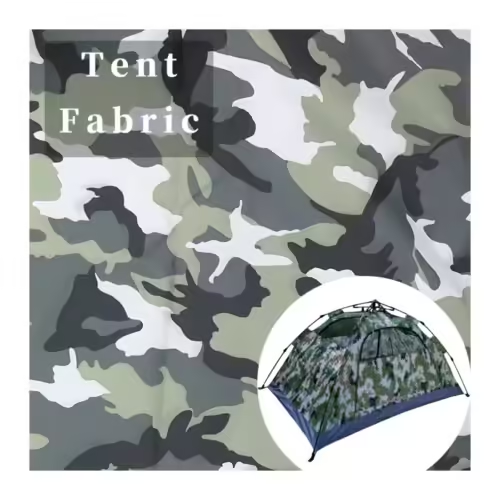

While specifically designed for paragliders, this fabric’s properties make it suitable for a range of other applications. It can be used in the production of lightweight tents, kites, and other outdoor gear where strength, lightweight, and weather resistance are paramount.

Applications:

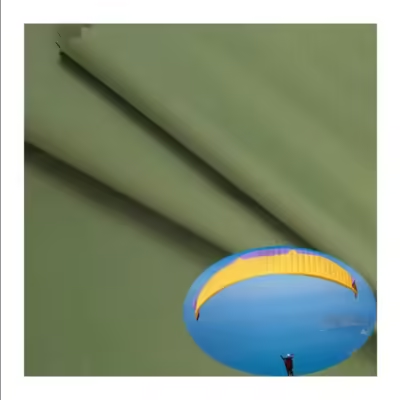

– Paragliders:

The primary application of this fabric is in the construction of paragliders. Its lightweight nature, combined with superior strength and weather resistance, makes it the perfect choice for creating high-performance paragliding wings.

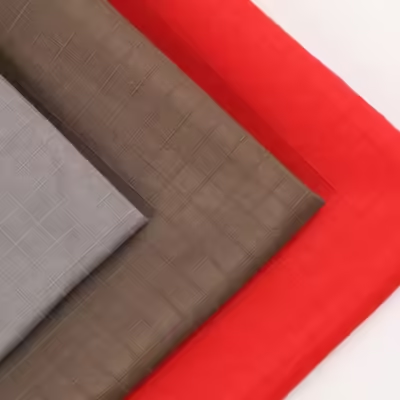

– Outdoor Gear:

The fabric’s properties also make it ideal for other outdoor gear, such as lightweight tents, tarps, and kites. Its durability and weather resistance ensure that it can withstand the elements, providing reliable performance in various outdoor activities.

– Technical Apparel:

The fabric can also be used in the production of technical apparel, such as windbreakers and rain jackets. Its lightweight and water-resistant properties make it suitable for creating garments that offer protection without adding unnecessary weight.

Care Instructions:

To maintain the performance and longevity of the 20D 380T PU Silicone Coated Nylon fabric, we recommend the following care instructions:

– Hand wash with mild soap and cold water.

– Avoid using bleach or harsh detergents.

– Air dry in a shaded area to prevent UV damage.

– Store in a cool, dry place when not in use.

Conclusion:

Our 20D 380T PU Silicone Coated Nylon fabric is the ultimate choice for paragliders and other outdoor applications. Its combination of lightweight, strength, and weather resistance ensures that it meets the demanding requirements of paragliding enthusiasts and professionals. Experience the superior performance and reliability of our high-quality nylon fabric and elevate your paragliding adventures to new heights.

Reviews

There are no reviews yet.