Introduction

ESD (Electrostatic Discharge) fabric plays a vital role in protecting electronics from static electricity. It might seem challenging to find the right ESD fabric, but there’s no need to worry. To make things easier, this guide will walk you through some key points. By following these tips, you can make a smart choice and find the best ESD fabric for your needs. Let’s dive into what makes ESD fabric effective and how you can select the right one.

Key Features of Good ESD Fabric

Material Composition

First, let’s talk about the materials used in ESD fabric. Common materials include polyester, nylon, and carbon fibers. Each type has its own benefits, so let’s look at them:

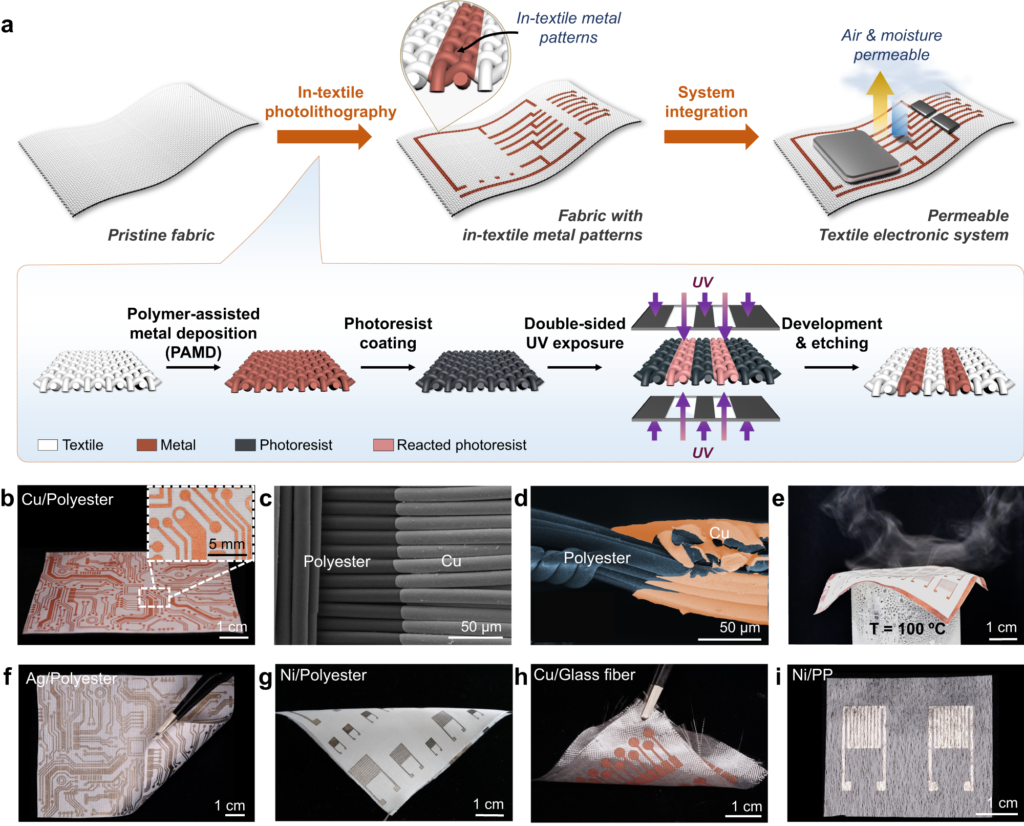

- Polyester and Nylon: These materials are popular because they are strong and cost-effective. Polyester is resistant to wrinkles and stretching. Meanwhile, nylon is known for its strength and flexibility. Therefore, both are good choices for many applications.

- Carbon Fibers: These are known for their excellent static control. Although they may be more expensive, their performance often makes them worth the extra cost. For example, carbon fibers are great for high-tech environments where managing static is essential.

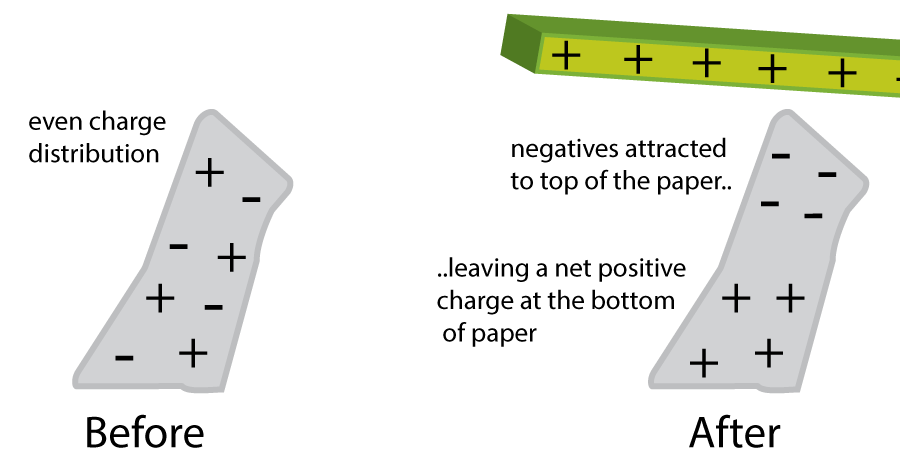

Electrostatic Discharge Properties

Next, you need to evaluate how well the fabric handles static electricity. To do this, consider the following key properties:

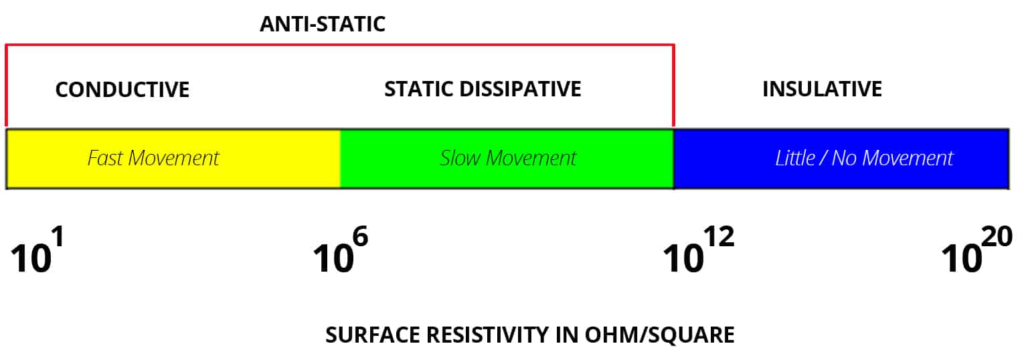

- Surface Resistivity: This tells you how well the fabric resists electrical flow. Typically, good ESD fabrics have a surface resistivity between 10^6 and 10^9 ohms. Fabrics within this range are effective at controlling static electricity. As a result, they provide excellent protection for sensitive electronics.

- Charge Decay Time: This measures how quickly the fabric can get rid of static charges. A shorter charge decay time means better performance. For instance, a fabric that releases charges in under 0.1 seconds is ideal for keeping areas static-free.

Comfort and Wearability

Comfort is also an important factor, especially if the fabric is used in clothing or protective gear. Here’s what to consider:

- Breathability: The fabric should allow air to pass through it. This helps keep you cool and comfortable, especially if you wear it for long periods.

- Softness: Choose a fabric that feels soft against your skin. Doing so will help prevent irritation and keep you comfortable. Additionally, a soft fabric is less likely to cause discomfort, especially if you wear it for long periods.

- Flexibility and Fit: The fabric should be flexible and fit well. This is important because it ensures comfort and allows for easy movement. Furthermore, a good fit and flexibility are crucial, especially in active work environments where you need to move around freely.

How to Check Fabric Quality

Standards and Certifications

To ensure you pick high-quality ESD fabric, check for these standards and certifications:

- Industry Standards: Look for fabrics that meet standards such as ANSI/ESD S20.20 or IEC 61340-5-1. By adhering to these standards, you can be confident that the fabric performs well and provides reliable static control.

- Certifications: Fabrics with certifications from trusted organizations are more reliable. For example, ANSI/ESD S20.20 certification means the fabric has passed important tests.

Testing Methods

Good ESD fabric should be tested for:

- Surface Resistivity Tests: These tests measure how well the fabric resists electrical flow. Therefore, it is essential to ensure that the fabric’s resistivity falls within the appropriate range to meet your specific needs.

- Additional Tests: Other tests, such as tensile strength and abrasion resistance, assess the fabric’s durability. Consequently, these tests reveal how effectively the fabric can handle everyday use.

Supplier Reputation

Choosing a reliable supplier is crucial. Here’s how to evaluate them:

- Reviews and Feedback: First, read reviews and feedback from other customers. Additionally, positive reviews often indicate that the fabric is of good quality and the service is reliable.

- Track Record: Be sure to check the supplier’s history. In addition, a supplier with a long track record of providing quality ESD fabrics is generally a reliable choice.

Choosing the Right ESD Fabric

Application Needs

Different applications require different types of ESD fabric. Consider the following:

- Cleanroom vs. Manufacturing: Cleanrooms might need stricter standards than general manufacturing. So, ensure the fabric meets the specific needs of your application.

- Special Features: Some applications might require special features, such as extra static control. Therefore, make sure the fabric has these features.

Customizability

If you need custom features, check if the supplier offers them:

- Custom Sizes and Colors: If you need specific sizes or colors, then ensure that the supplier can accommodate these requirements. Additionally, confirming their ability to provide customized options will help you find the best fit for your needs.

- Special Features: Some suppliers offer custom solutions for unique needs, such as enhanced protection.

Cost Considerations

Balancing cost and quality is important. Here’s what to keep in mind:

- Cost vs. Quality: Higher-quality ESD fabric may cost more, but it often provides better performance and durability. So, determine if the higher cost is worth the benefits.

- Long-Term Investment: Investing in better-quality fabric can save money in the long run due to its longer lifespan and better performance.

Tips for Buying ESD Fabric

Research and Comparison

Before buying, do your research:

- Compare Products: Examine various ESD fabrics and suppliers. Additionally, compare their features and prices to identify the best option that suits your needs.

- Check Supplier Credentials: First, verify the supplier’s reputation and product quality through reviews and certifications. Furthermore, this step ensures that you are choosing a reliable and high-quality source.

Expert Advice

Consulting experts can be helpful:

- Seek Recommendations: Experts can offer valuable advice based on their experience. Consequently, this guidance will help you make a more informed and better choice.

Sample Evaluation

Request samples before buying in bulk:

- Test Samples: Testing samples allows you to check the fabric’s quality and performance before making a large purchase.

Conclusion

Choosing high-quality ESD fabric is essential for protecting electronics from static damage. By focusing on key features, checking standards and certifications, and choosing a reliable supplier, you can find the best fabric for your needs. Also, consider the application requirements, customizability, and cost. Do thorough research, seek expert advice, and test samples to make an informed decision.

With this guide, you can confidently select ESD fabric that not only offers reliable protection but also meets all your specific needs and requirements.

Introduction to ESD Fabric:

- Electrostatic Discharge (ESD) Protection – Understanding ESD and Its Importance – ESI’s overview of ESD and its significance in electronics.

Material Composition:

- Types of ESD Materials and Their Applications – OhmTek’s explanation of different ESD materials.